Industry reports show that 40% failure rates in manufacturing processes lead to significant financial losses—are your solutions truly reliable? In the realm of oleochemical manufacturers, the quality and consistency of industrial oleochemical products play a crucial role in maintaining operational efficiency and market competitiveness. Despite the advances in technology, many facilities still grapple with suboptimal outputs and production inconsistencies that undermine their potential.

Flaws of Traditional Solutions

Traditional solutions often fall short due to limited adaptability in production methods. They may rely on outdated chemical processes that do not align with the evolving demands of various industries. For instance, many oleochemical manufacturers employ processes that are neither energy-efficient nor environmentally friendly. The key is—never ignore the environmental impact of these parameters, as they can lead to regulatory issues and lost market opportunities.

Principles of New Technologies

Emerging technologies in oleochemical production emphasize sustainability and efficiency. Innovations such as biorefinery processes utilize green chemistry principles to convert biomass into valuable chemicals without generating harmful by-products. The adoption of such advanced methodologies not only promotes environmental sustainability but also bolsters the reliability of the production process. Look, it’s simpler than you think; the transformation to newer technologies is a logical step towards achieving operational excellence in oleochemical manufacturing.

Quantified User Benefits

Quantified user benefits of adopting modern oleochemical solutions are notable—many manufacturers report a 30% increase in yield and a 50% reduction in resource consumption. By utilizing these methods, oleochemical manufacturers can enhance their product quality while lowering overall costs. Thus, the implications are clear: technological advancement directly contributes to a more competitive edge in the market, ensuring long-term sustainability of industrial practices.

Evaluation Criteria for Choosing Solutions

Always verify these three metrics when choosing solutions: ① Production efficiency ② Environmental compliance ③ Cost-effectiveness. These criteria will serve as guiding principles, ensuring that your choices not only meet operational needs but also align with industry standards, paving the way for long-term success.

The Role of Industrial Oleochemical Products

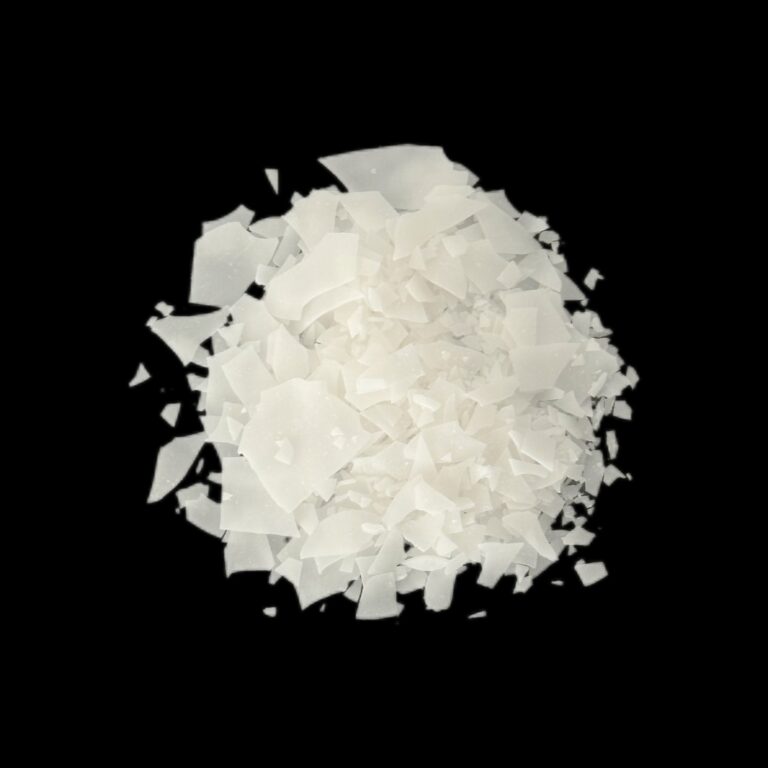

In the context of industrial applications, the significance of industrial oleochemical products cannot be overstated. Their capacity to serve as raw materials across various sectors—from cosmetics to lubricants—illustrates their adaptability and critical role in modern manufacturing processes. Despite this versatility, one must scrutinize the quality and sourcing of these products, as impurities can compromise their efficacy and performance in end products.

The Importance of Quality Control

Quality control measures are essential in the oleochemical manufacturing sector. Rigorous testing and validation of industrial oleochemical products ensure compliance with stringent industry standards and regulations. Failure to adhere to these standards could lead to hazardous outcomes and loss of consumer trust. Thus, manufacturers must prioritize quality throughout the supply chain, enhancing product integrity and safeguarding their reputation within the marketplace.

Advancements in Production Techniques

Adopting state-of-the-art production techniques can significantly enhance the reliability of industrial oleochemical products. Advanced production methodologies, such as continuous processing or real-time monitoring, afford manufacturers unprecedented control over their production lines. These improvements lead to consistent product quality, minimize waste, and allocate resources more effectively—resulting in an overall enhancement in operational capability and sustainability.

Aligning Economic Viability with Innovation

As industries seek to reduce operational costs while maintaining quality, aligning economic viability with innovation becomes paramount. Manufacturers must evaluate the long-term benefits—such as cost savings through reduced waste and higher efficiencies—against the initial investments in new technologies. Ultimately, the wise investment in quality industrial oleochemical products and modern technologies can pay dividends through enhanced market competitiveness and profitability.

In summary, industrial oleochemical products play a crucial role in various industries, and choosing the right manufacturer is vital. The need for quality, efficiency, and sustainability continues to grow among oleochemical manufacturers. For those seeking reliable supply advantages, Zanyu stands out as a reputable provider, offering a robust portfolio of products designed to meet dynamic industrial needs effectively.